Magneetventielen voor cryogene toepassing LN2 LCO2

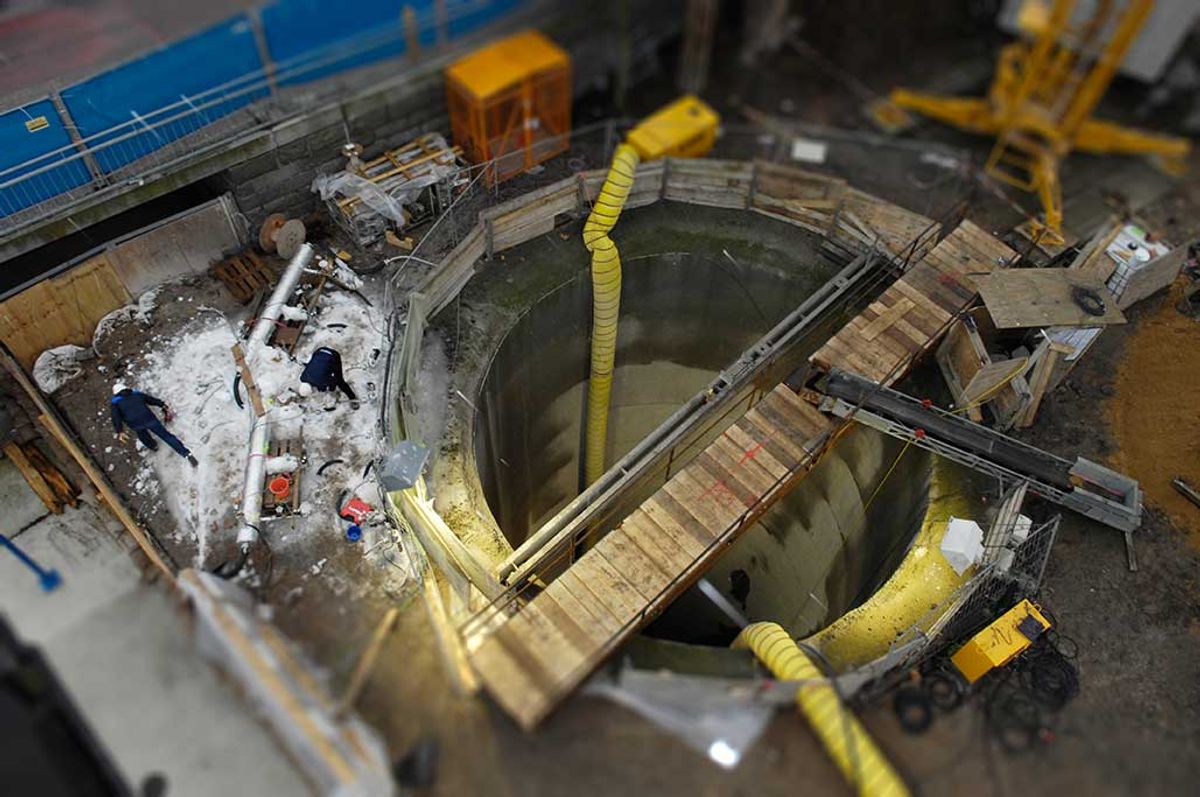

De behandeling en controle van vloeibare cryogene gassen, namelijk vloeibaar kooldioxide (LCo2) of vloeibaar stikstof (LN2) tot -196°C, wordt uit veiligheidsoogpunt steeds belangrijker. Cryogene magneetventielen worden gebruikt voor het afsluiten van leidingen onder druk, bijvoorbeeld voor het koelen van cement en het bevriezen van grond, en voor het regelen van gekoelde klimaatkasten voor laboratoriumtoepassingen en het invriezen van levensmiddelen.

The handling and control of liquefied cryogenic gases, namely liquid carbon dioxide (LCo2) or liquid nitrogen (LN2) at temperatures of up to minus 196°C is given more and more importance for technical safety considerations. Cryo solenoid valves are used for blocking pressurized lines, e.g. for cement cooling and soil freezing and for the control of air conditioning cabinets for laboratory application and food freezing.

Advantages of solenoid valves

Solenoid valves are safety-relevant „fail safe“ shut-off devices. If electric voltage is removed the solenoid valves switch to the right position, either directly by the spring power and/or by using the initial pressure.:

- CLOSED (at NC function)

- OPEN (at NO function).

These valves are generally called directly controlled and force-controlled or servo controlled solenoid valves.

Safety first

For cryogenic applications, safe valve function is given highest priority as a failure of the valves would have far-reaching implications. Besides objectionable production downtime and product destruction there is a high risk to life.

In case of uncontrolled escape of liquefied carbon dioxide (LCo2) the liquid gas quickly evaporates thus generating large quantities of gas. Oxygen is displaced from the surroundings and thus acts suffocatingly. In case of direct contact cryogenic liquefied nitrogen (LN2) causes freeze burns or frostbites.

Experience

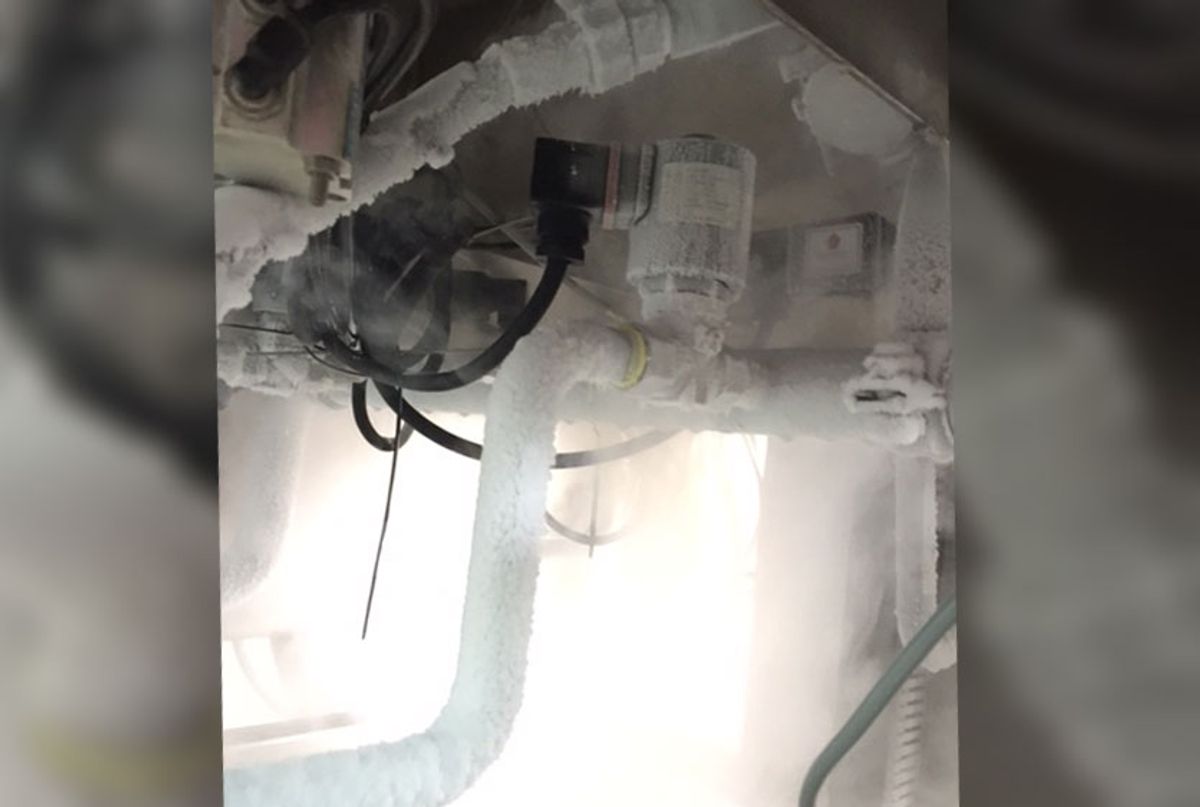

has shown that many cryo gas users have unfortunately not only made positive experience regarding the perfect function of automatic valves. Leakages and valve tappets become stuck due to the exposure to moisture or components with incorrect sizes are, to our great regret, a major uncertainty factor because this enormously affects the production cycle or the control of cold input as mentioned at the beginning.

Buschjost Solenoid Valves a innovative company in the Northrhine-Westphalian city of Vlotho has problem solvers for cryogenic applications in its range.

Problem solver & users‘ darling

E.g. the 2/2-way solenoid valve Type 2/738 which has been especially developed for cryogenic application in continuous operation and has been used successfully for several years. It is a question of safely controlling the high temperature differences Δt 230°C between the ambient air and the medium temperatures; no simple task as solenoid valves, based on their design, have gliding elements from their actuator to their piston and a permanent outer icing depending on their application has to be anticipated.

Therefore it goes without saying that the solenoids must have special protection against penetrating moisture. In the last years the solenoid valve range for cryo-applications was expanded thanks to continuous customer demands. Today connection sizes from G1/4 to G6/4 and pressures of up to 200 bar are manageable .