Buschjost product range & service

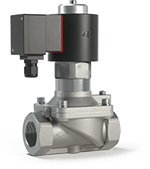

The Buschjost process valve program includes a wide range of different solenoid valves and air-controlled valves for controlling and regulating gaseous, liquid media in pressurized pipelines.

Solenoid valves block, relieve, distribute or mix gaseous and liquid media of various chemical compositions depending on pressure and temperature.

Versatility is key. Forced-Pilot-Operated valves combine the advantages of Servo-Assistant and Direct-Acting valves.

Achieve a lot with little energy. The specification of the minimum pressure difference precedes the maximum possible pressure difference.

The professional with extra power. The magnetic force must act against the medium pressure and the spring.

Cryogenic solenoid valves for cryogenic liquids and gases down to -200°C. Win your advantage from the features: fast response, defined fail-safe position NC or NO and pure electrical. Ask also specifically for cryogenic valves for use in the food industry.

The maximum medium temperature depends on the type of sealing element and the material. For this section we classify valves for temperatures between +110°C and +300°C.

We define high pressure when the operating pressure exceeds 40 barabs. High-pressure valves can be selected as direct-operated, forced-pilot-operated and servo-assistant valves. The valves have special housing and sealing materials. The solenoid tube system is also exposed to pressure, which requires special measures to ensure pressure stability. The limit is 1050 bar overpressure and is of exemplary interest for the green transformation in the H2 industry.

Control air present? If YES, then you can take a look at these valves.

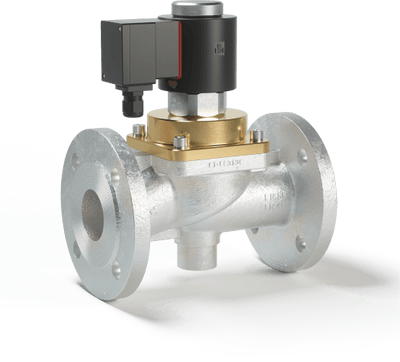

We combine the advantages of the control types direct, servo and externally controlled. The larger the valve and the higher the pressure, the more effective the use of these valves. For water control, these valves are preferably equipped with a damping cone to prevent the water hammer.

Obsolete Valve category with reduced range of options and limited to a very small number of applications. This category has a permanent place in the "Riding a Dead Horse" section and will be removed from the programm.

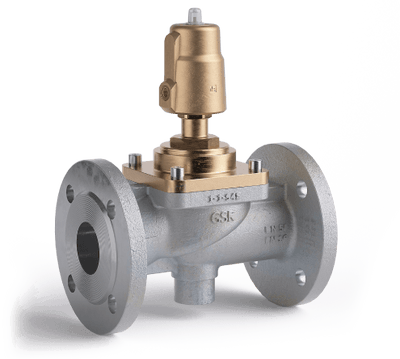

Best Value for Money Use the existing compressed air system to control the stroke actuator and you have a long-life valve for a wide range of applications. The well-known 63 series, whose forerunner, the 62 series, was launched in 1971 with its characteristic formed blank cylinder, is the best indication of this high-quality product category. Even today, 25 years after the end of production of the 62 series, repair and service enquiries are still coming in from all over the world.

Seat valve with disc seal and lifting spindle, or ball valve, 90°rotation of the ball in sliding shells. With extension for cryogenic applications down to -200°C. Reliability and high switching cycles are on board as standard. Of course with spring-loaded closing (NC) or spring-loaded opening (NO)

We say yes, with the proven ingredients for electro-pneumatic poppet valves. Already many standard valves have +200°C medium temperature written into their specifications. With a little more german engineering, the +400°C is achievable.

Up to 160 bar our favourite, above that it is not our shining star in the sky. Our range is equally thin. We avoid the effort of sealing 4 points: To the valve outlet, medium to the outside, medium to the control chamber, control chamber to the environment. But no rule without exception!

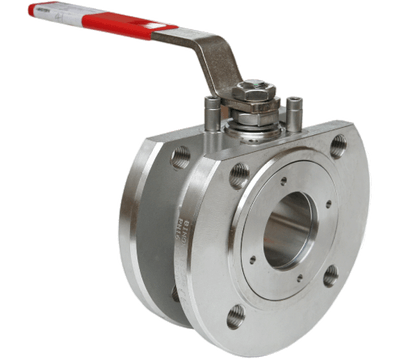

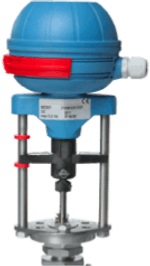

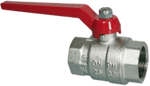

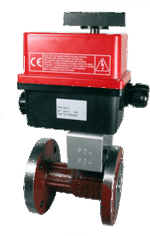

A ball provided with a bore and guided by sliding shells in a geometrically adjusted housing is called a ball valve. The 90° angle of rotation opens or closes the way.

Ball valves with hand lever

Ball valves with pneumatic actuatur, single or double acting

Ball valves with electric actuator