Válvula de bloqueo y purga doble (electroválvula de cierre doble)

Si se producen problemas peligrosos inesperados como resultado de un mal funcionamiento de las válvulas de proceso y se espera un aumento de los peligros como consecuencia de ello, las válvulas deben construirse en una disposición redundante.

In case of malfunctions of the process valves unexpected dangerous problems occur and you therefore have to expect increased higher risks, the valves have to be designed in a redundant arrangement.

2 main valves connected in series open and close simultaneously.

An additional electrical position control records the valve switching position:

- Valve(s) open or valve(s) closed.

- EAny possible leakage at the 1st main valve is safely overcome by an optional central relieve valve which is normally open (NO).

Our customers in the gas facilities and environmental technology field

Unprocessed biogas delivered by gas suppliers is stored in underground salt caverns (depth up to 1500 m). To make the biogas ready for use it is taken out of the storage site, preheated in a gas processing plant, its pressure is reduced, and finally it is dried by means of glycol (dehumidified).

Solenoid valves for Vent Gas

When biogas is being processed vent gas are

generated. Vent gas are by-products based on

hydrocarbon in a gaseous phase, being transformed

to the condensate phase when being

cooled off.

The generated vent gas mixture is generally burned.

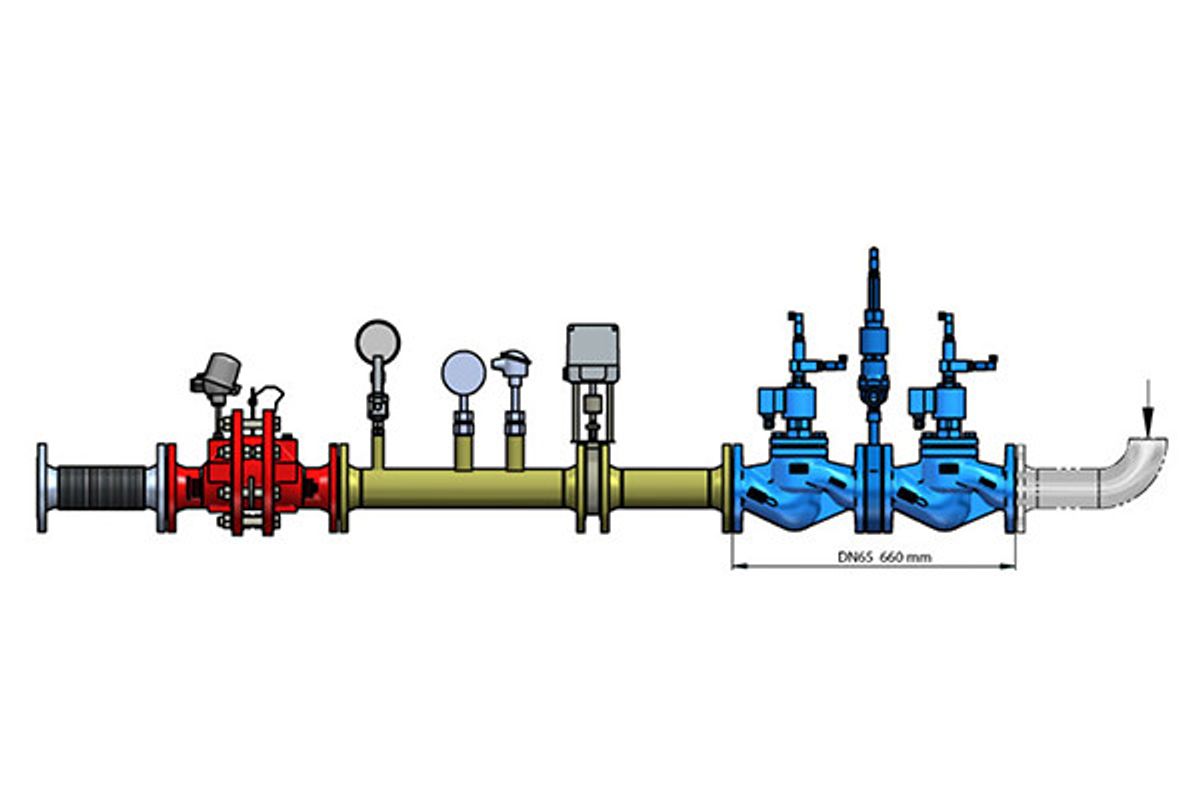

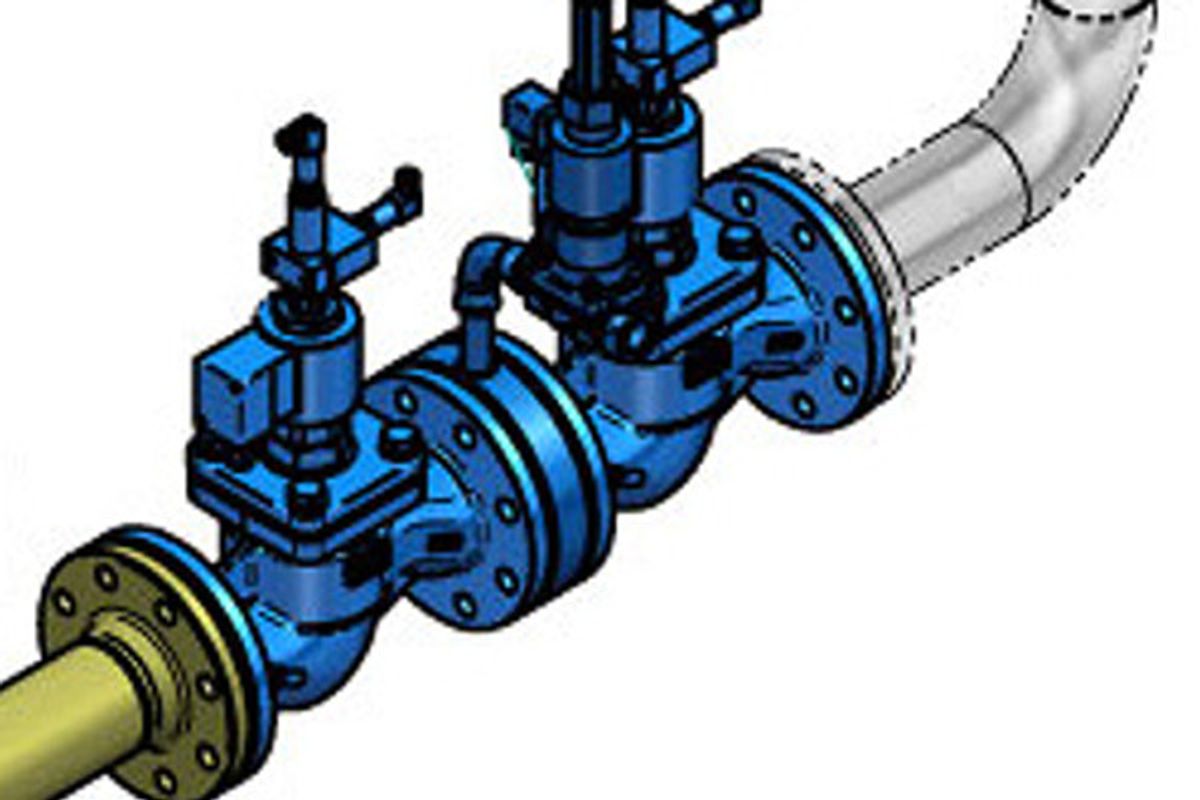

A valve combination in redundant arrangement is used for isolation:

- 2 main valves 24-NC series DN65

- 1 release valve 48-NO series G1/2 to drain off the leakage gas

- Intermediate flange with pipe extension for leakage rate valve, suitable for isolation.

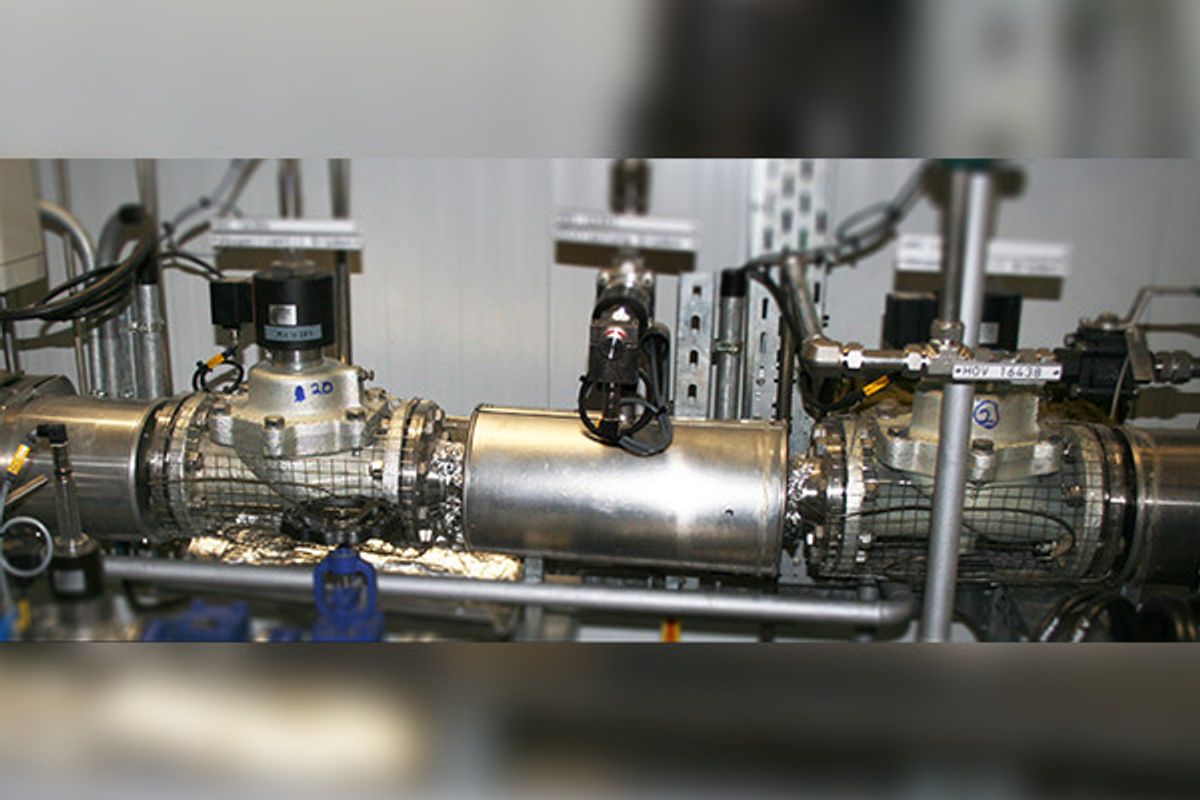

The vent gas input pressure is 500 mbar at temperatures between +140 °C and +160 °C.

Difficulty Problematic

When the vent gas is cooled, it can be streak

out and condensate and in the end a subsequent

formation of deposits on the valve seat

can cause permanent leakage.

To counteract this in the best possible way valves

from special materials are chosen. Furthermore

the operator has to make sure that the

isolating combination is continuously heated to

ensure good isolation.