12/2021 Testing for functionality in cryogenic environment

Target: Permanent operability of the valve A5244/0604/1012-F 24VDC in cryogenic environment shall be tested.

Boundary condition:

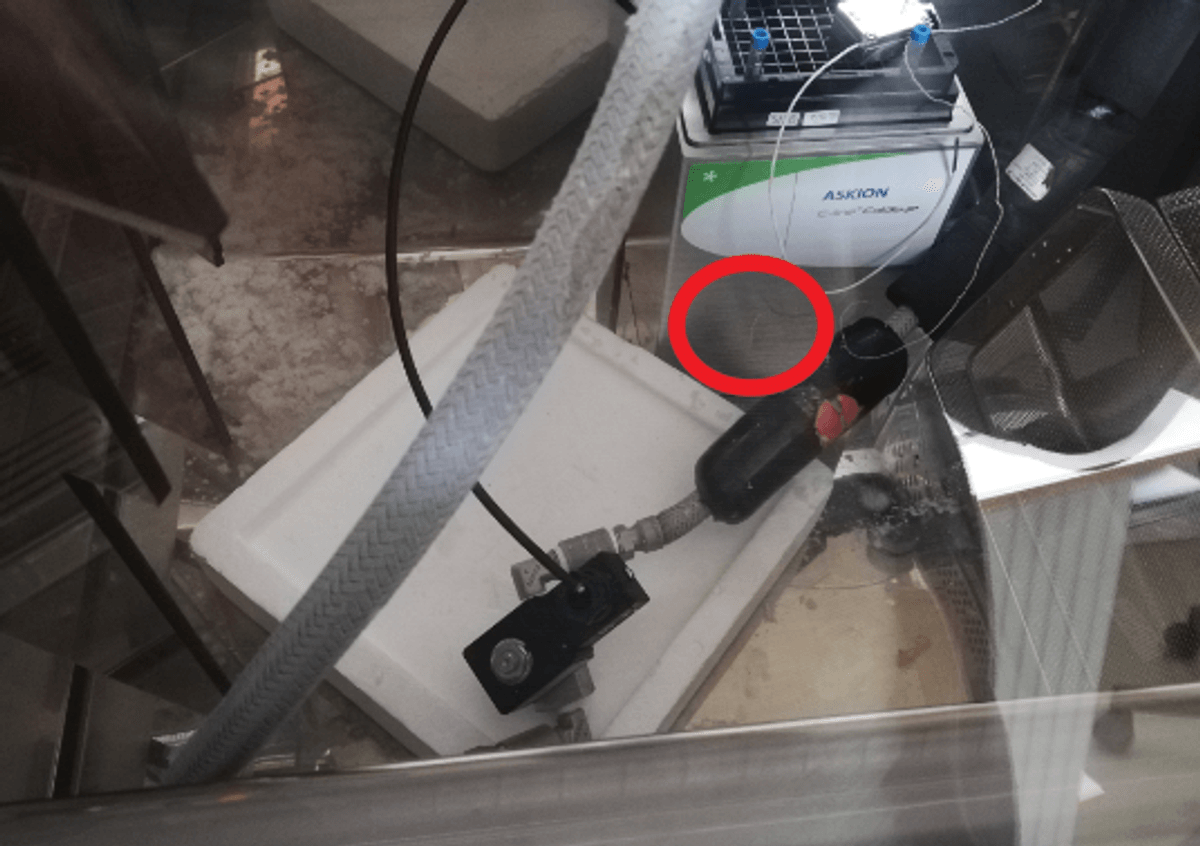

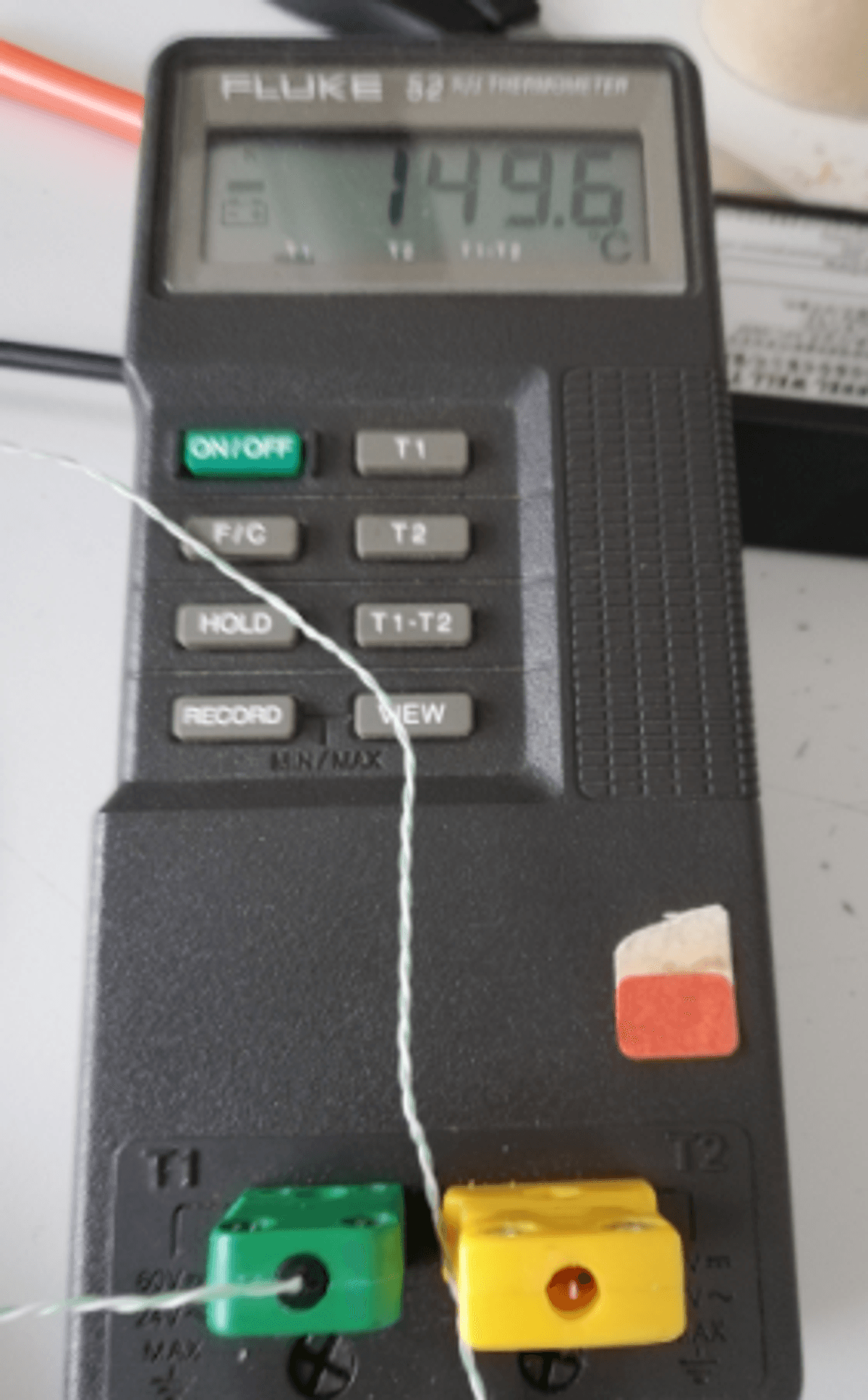

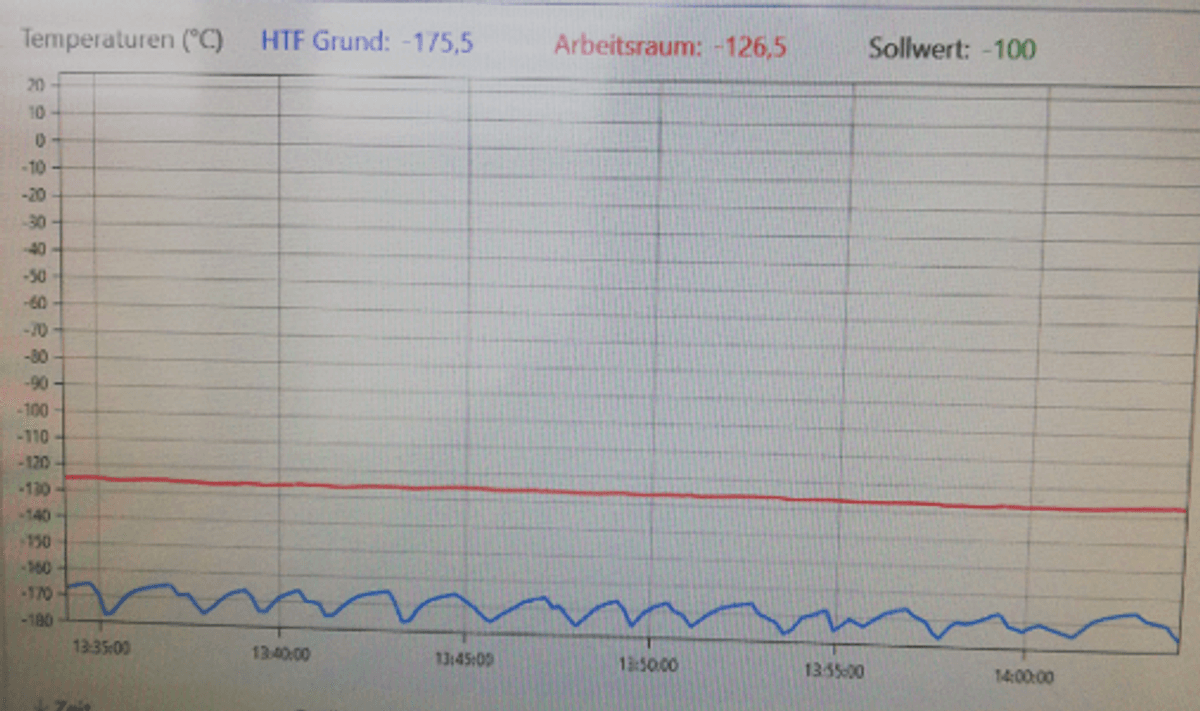

Valve is located inside the working chamber T ~ -150°C (see Fig.1). LN2 flows continuously through the valve. On the inlet side, the hose comes directly from the Apollo tank. On the outlet side, a hose leads into the HTF Direct use of the valve to control the LN2 level, or temperature, by means of internal control cycles of the HTF‘s LN2 supply.

Realisation:

Nonstop test over 3 days (01.12.-03.12.2021).

Internal WB-side control of the HTF valve was tapped directly to flow through the valve with LN2 and thus simultaneously take over the temperature control.

Insofar as a stable temperature is established in the HTF over a long period of time, the functional capability (ability to close) of the valve is ensured.

Apollo containers were regularly refilled.

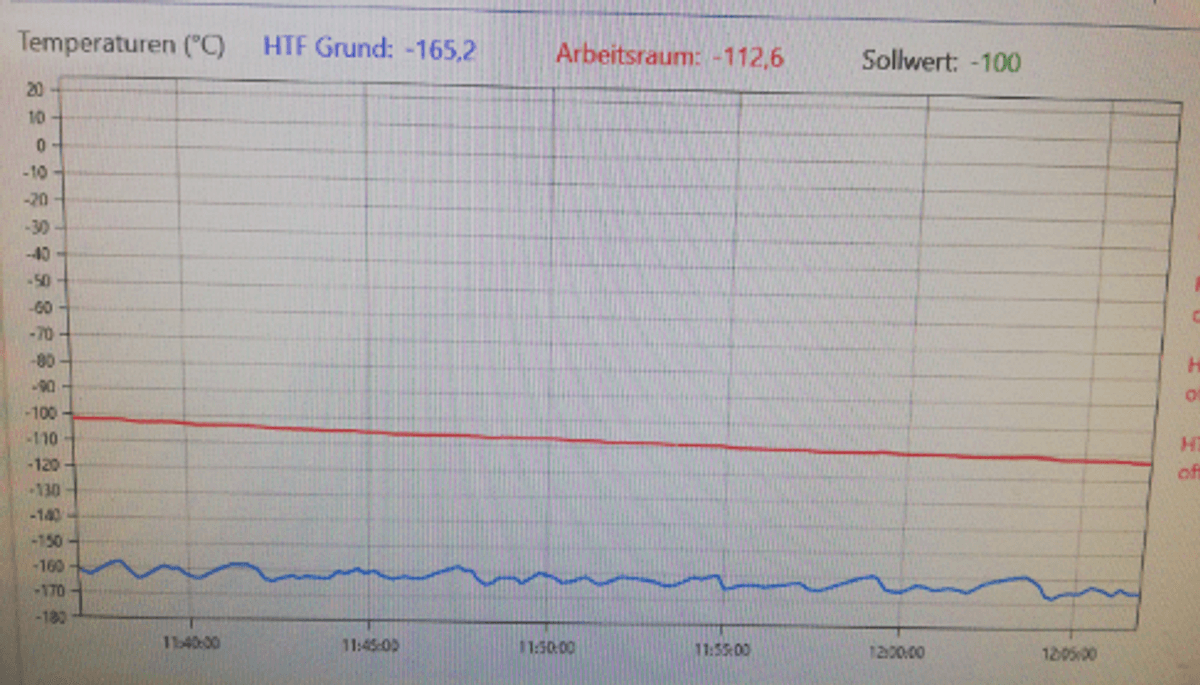

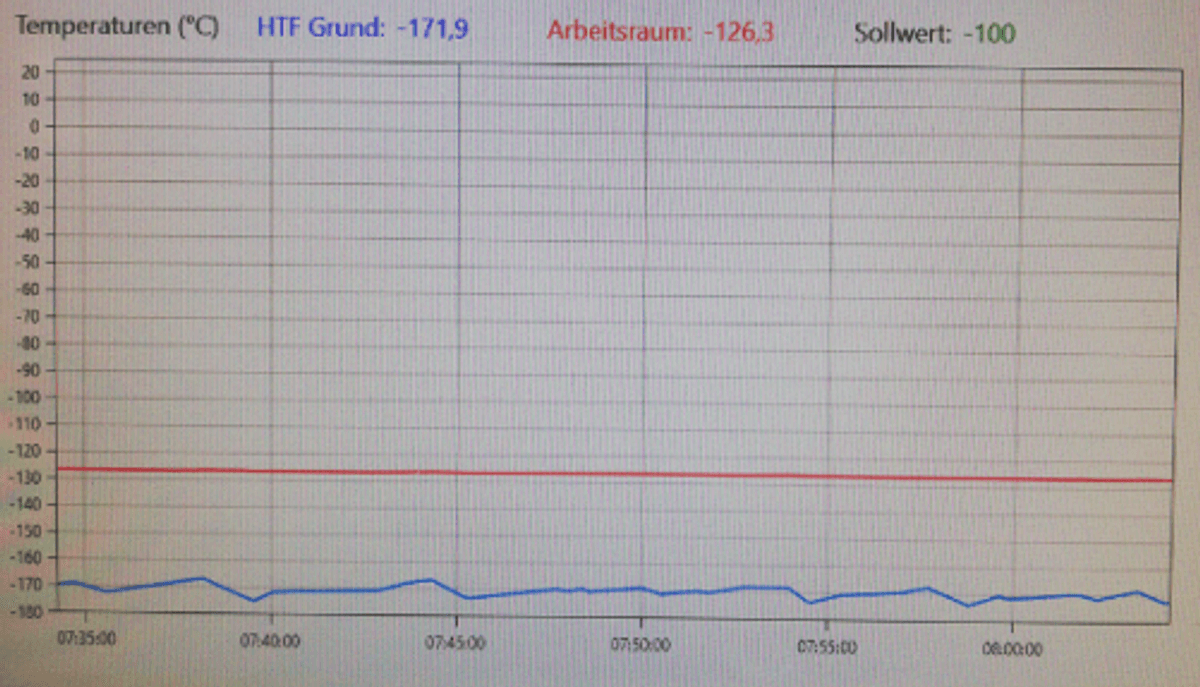

The temperature of the „working chamber“ (see Fig.3-5) corresponds to the temperature at the level of the sensor installed on the WB side.

Position of the valve at the bottom of the working chamber at temperatures that are approx. 30K lower (see fig.5).

Summary:

Permanent functionality of the valve A5244/0604/1012-F 24VDC could be confirmed. The valve has operated properly for 3 days in cryogenic conditions (T ~ -150°C).

The valve was stored within a cryogenic LN2 environment with constant supply and OPEN/CLOSED control of LN2 -196°C.

The valve did not show any wear or degradation during the 3-day test or afterwards.

The information in the data sheets is always authoritative for you. Any knowledge gained from this must not be relied upon and is of a purely informative nature!