Importance of individual special products for hydrogen technology

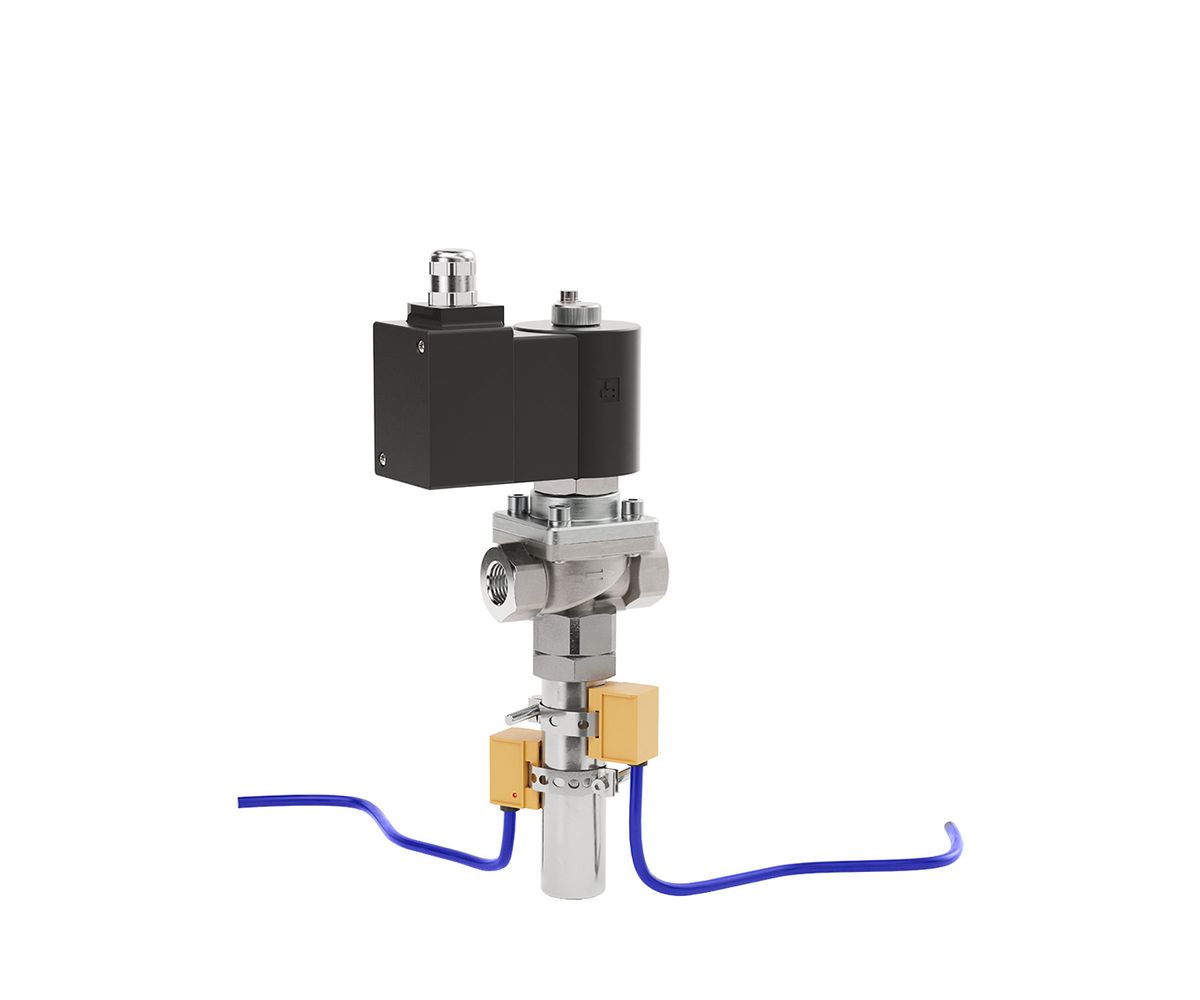

Solenoid valves are absolute specialists for hydrogen up to 900 bar, whose performance depends heavily on the adaptation to the working environment.

Valves for hydrogen must meet criteria that deviate from the standard. Since hydrogen is up to 14 times lighter than air, high requirements are placed on permanent tightness of 10-6 mbar l/s at the valve seat and tightness to the outside atmosphere. Often these requirements go hand in hand with high system pressures and Zone 1 explosion protection.

We are tackling this challenge on two levels. Firstly, the regular valve range is deliberately so broad that it covers many requirements for hydrogen applications. The diversity of variants relates to both the type of control system and the materials used, as well as the nominal widths of the connections. All in all, customers will find a broad portfolio that has been successively developed taking into account common areas of application.

In some cases, however, even this range is not enough. And then special solutions such as the safe shut-off of system pressures of 500 bar, 700 bar even up to 1000 bar come into play. These are individually tailored to our customers' needs, and our team is on hand to provide advice during all phases.

We, as Buschjost Solenoid Valves, contribute our part and shape the development sustainably by going new ways. Get acquainted with our innovative valve configurator Ventilscout or the latest development, Offertool Roadrunner, whose name is program, a technically sophisticated offer portal that creates a customized offer for you in a short time.

A look at the variety of options shows that all imaginable solutions can be created. The following links lead to the H2-Techsheets. A tip from us, change the selection in master question 9 and you will get more options like normally open, feedback contacts, NPT, oil and grease free, manual override, UL approval and others.

2/2-way H2 solenoid valves

Safety during hydrogen application.

The fitting parts for H2 valves that are exposed to the medium pressure are carefully selected according to the intended use. Depending on the pressure rating, brass, high-quality stainless steels AISI 316 L, 318 LN are used. Suitable sealing materials FKM, PTFE, Peek, PCTFE complete the picture of the perfect hydrogen valve.