Soft-closing automatische ventielen voor watercontrole

Geen gemakkelijke eis van de klant, want alle bekende principes om waterslag te vermijden hebben voor deze specifieke toepassing ongewenste neveneffecten.

This is not an easy task as all known principles to avoid water hammer have undesired side effects for this special application:

You need:

Valves with fast opening and closing time that ensure avoidance of the feared water hammer. The maintenance cost should be reduced to a minimum, the design should be as simple as necessary and the construction as robust as possible.

Design

Based on 40 bar the pump pushes up to 90m3/h through the valve. Every closing process means a test for the material. Harsh braking of the water mass causes water hammers of up to the triple of the pump pressure. This results in over torqued manometers and differential pressure gauges and up to broken screwing and pipes. Consequently frequent service is required for the valve and the periphery.

Our customized solution meets the customer requirements:

A special valve has been developed based on the 26 series. To keep the water mass smoothly moving and to counteract water hammer we have considered to strongly reduce the centre zone in the valve. But the closing times did not meet the customer requirements. When taking this single measure the closing times would be definitely too long.

Solution

We have compensated the effects of closing time extension by several

methods. This means that the most important measures are taken inside

but also outside the valve.

The channels have been adapted to the operating conditions and a throttling

valve plus was fitted beneath the valve plate. Control air supply for

opening as well as exhaust air for closing are adjusted according to the

local conditions.

The result:

The valve switches within the time limit set by the customer. Water hammers

have been reduced to a minimum.

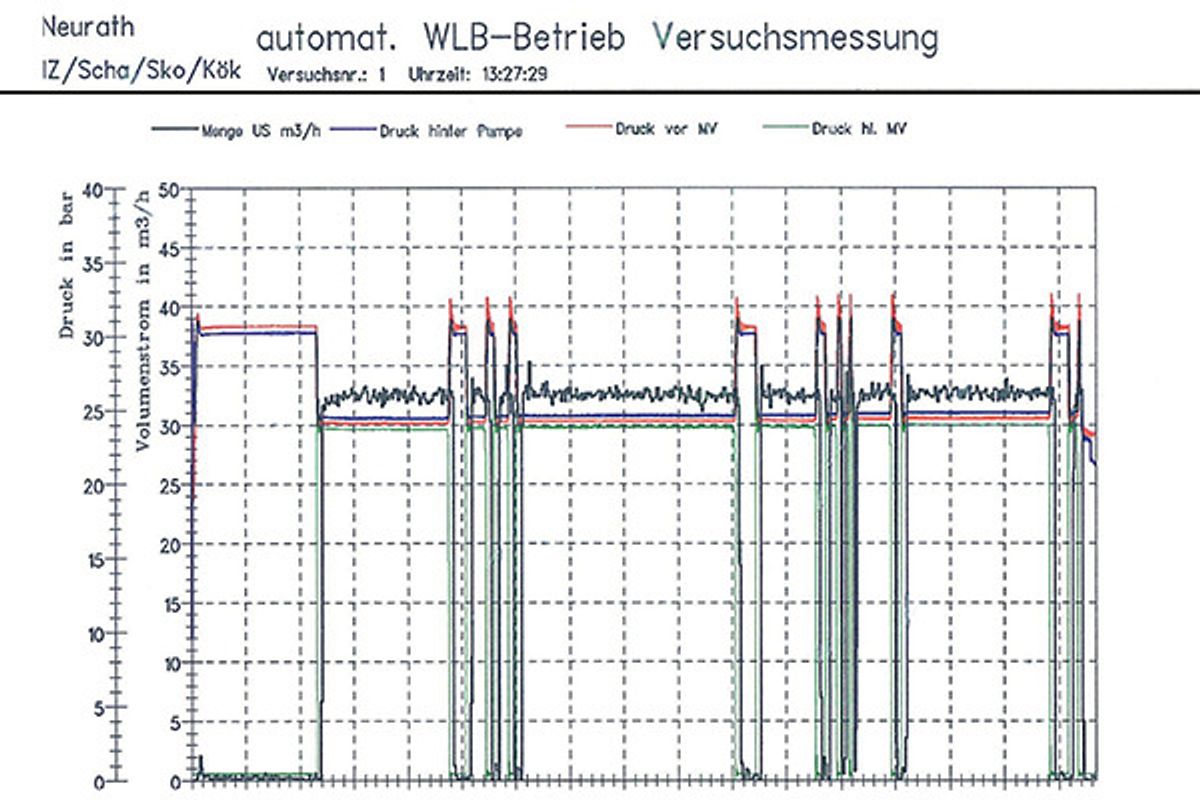

A recorded test measurement showed that the pressure peak in front of

the valve increased while closing to 33 bar for a short time. This is an

absolutely tolerable value which does not cause damage to the material.

In the test field we have documented as follows:

- Pressure condition directly behind the pump,

- pressure behind the valve,

- volume flow rate measurement.

positive side effect

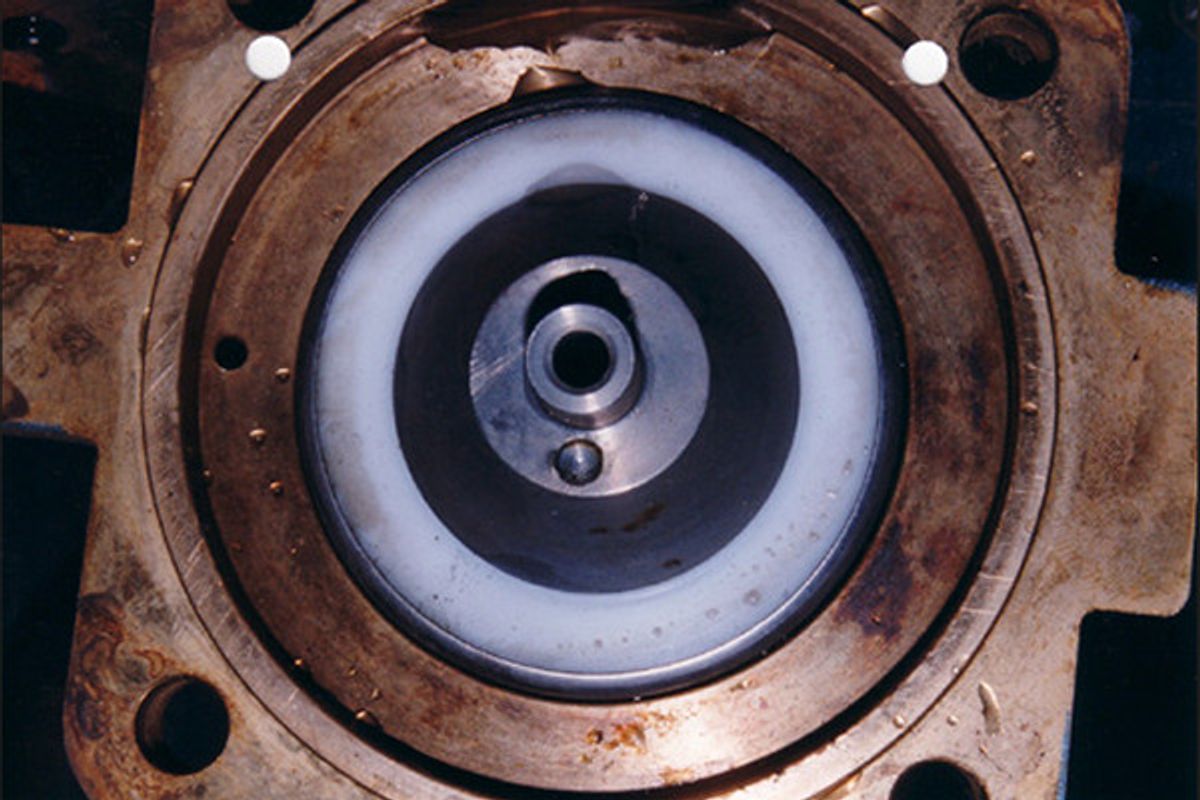

The optimized measures taken on the valve had also an effect on the

useful lifetime.

Although one of the competitors‘ valves showed failure symptoms such

as the loosening of the sealing element at the valve plate, this valve

solution was fail-safe. This positive effect has been achieved thanks to

the favourable streaming of the medium at the cone beneath the sealing

element.

„Hitachi-Power-Europe“ Order

Buschjost Magnetventile GmbH & Co. KG benefit from the expansion and upgrading of those coal-fired power plants that are now fossil fuel fired.

„Hitachi-Power-Europe“ order (continued)

Thanks to the fact that the reliability of our operating valves could be

proven, we signed a four-year contract for the delivery of valves in August

2007.

The delivery comprised valves for cleaning boiler walls by water jet. Up

to 12 valves can be used per boiler. The first valves for the power plants

- Walsum,

- Datteln,

- Maasflakte,

- Moorburg,

were supplied, further deliveries for the power plant operators

- RWE,

- e.on,

- Vattenfall,

- Eleketrabel (Belgien)

will follow by the year 2011.

We have had to meet special specifications:

The pressure-controlled shut off valve has to reliably retain the cooling tower water as well as the fluvial water of the same area. To fulfil the requirements of many different analyses austenitic steel was chosen for the fitting; further features are the feedback regarding the valve positions OPEN/CLOSED via inductive limit switches in three-wire technology, wiring adapted to the power plant with V1 90° connector from the manufacturer P&F or plug connections HAN 7D and/or HAN 8U from the Harting company.