Elettrovalvola per il congelamento del terreno

Per proteggere il terreno e l'acqua da crolli durante i lavori di ingegneria civile, ad esempio nella costruzione di gallerie, il terreno viene congelato. A tal fine, nel tunnel, nel pozzo o nella galleria vengono installate diverse lance di congelamento che vengono poi riempite di azoto liquido. In questo modo, nel terreno circostante si forma un corpo di gelo con l'azoto freddo a -196°C nel giro di pochi giorni, che arriva in profondità nel terreno.

The freeze lances required for this purpose consist of an inner and outer pipe and are introduced into the boreholes.

By feeding liquid nitrogen (LN2) through the inner pipe the surrounding ground is sufficiently cooled to ensure the formation of a freeze wall. Then the gaseous nitrogen (exhaust gas) flows through the annular gap between the inner and outer pipe to the outside.

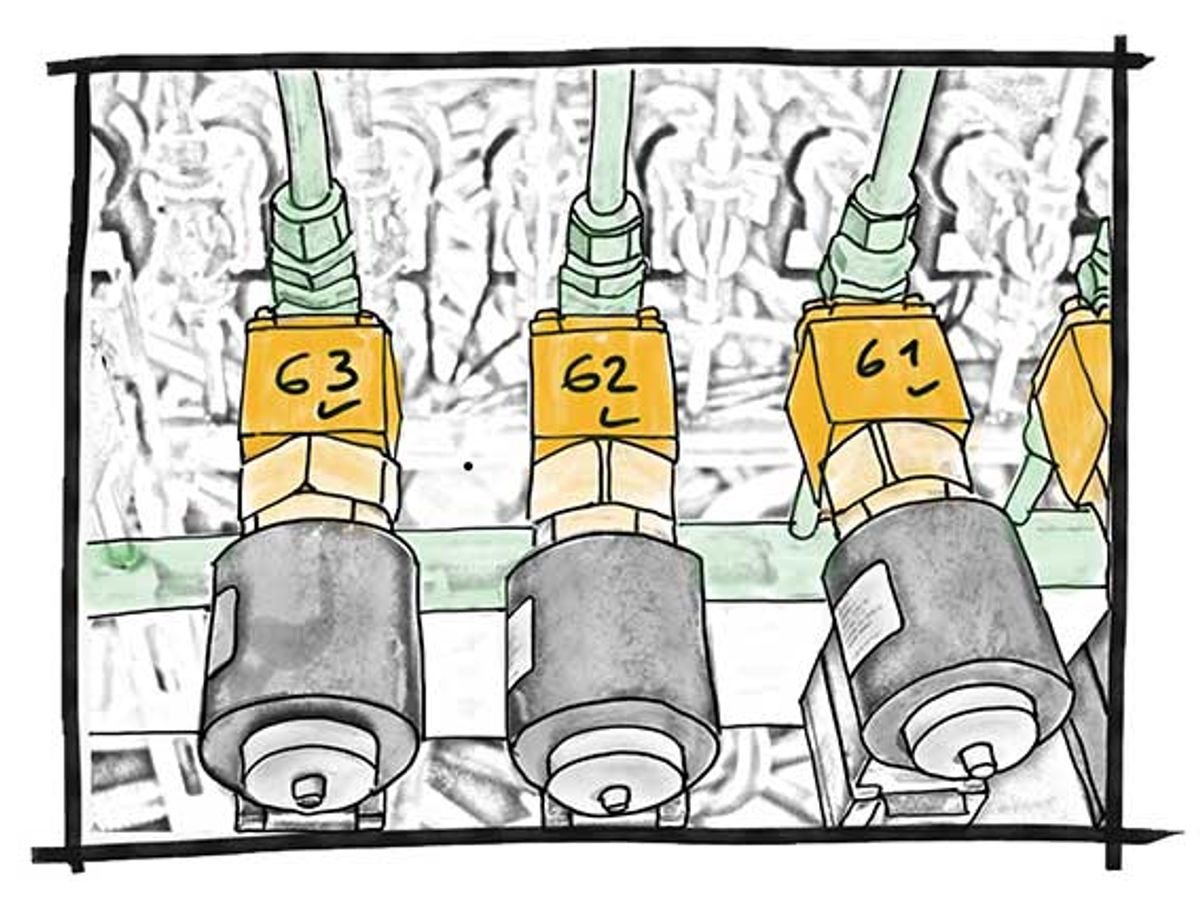

Nitrogen feeding to the freeze lances is carried out in a temperature-controlled way. A solenoid valve type 2/738 has been installed upstream of each freeze lance. Control of the solenoid valves is ensured by temperature sensors on the exhaust gas side.

The reliability of the solenoid valves is very important as nitrogen dosing is to be ensured by these valves. Often up to 80 solenoid valves are to be switched at 1-second intervals for many days or weeks during the tunnel construction term. A failure of the valves would cause a disturbance of sectional freezing fields and sustainably jeopardize the tunnel construction project.

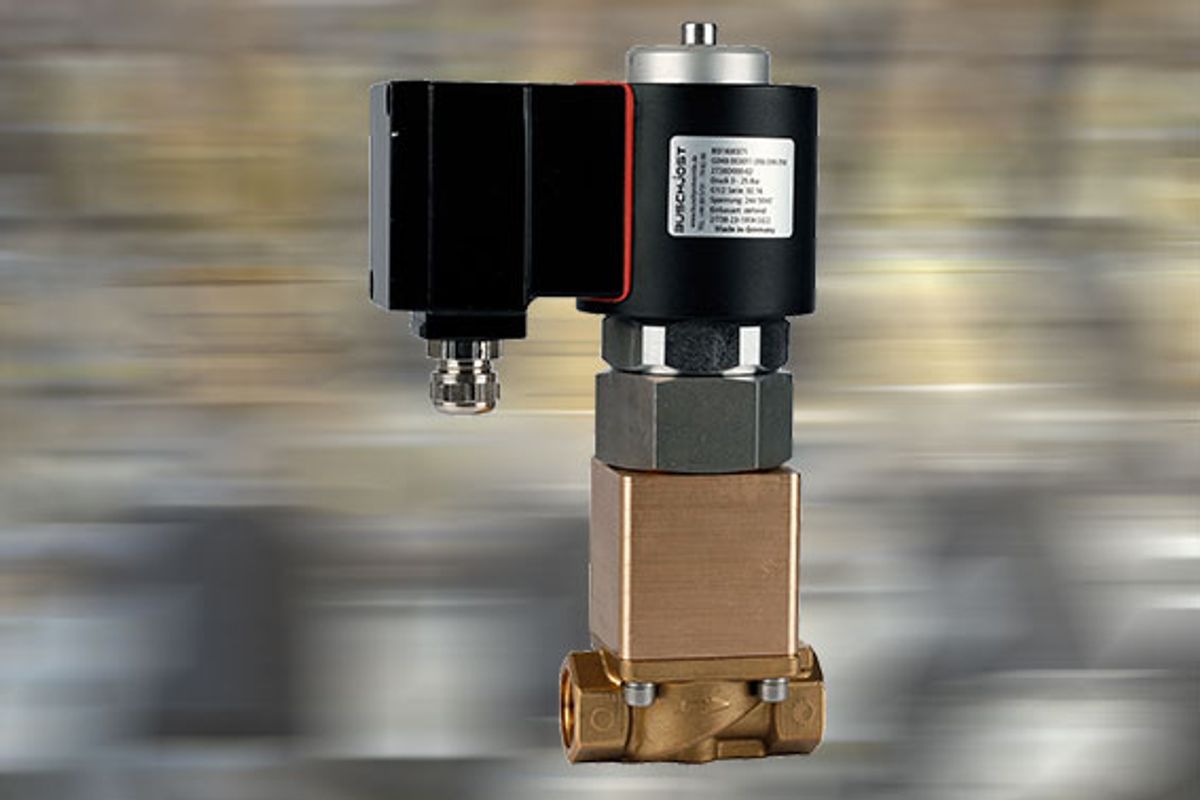

Developed, tested and successfully used:

Solenoid Valve, Cryogenic-Design

-

Typ 2/738-23-1004-S322

-

G1/2,

-

0-25 bar,

-

230V AC ,

-

NC,

-

liquid nitrogen (LIN) -196 °C